Chest of Drawers Part 2: Drawer grooves

But did it warp?

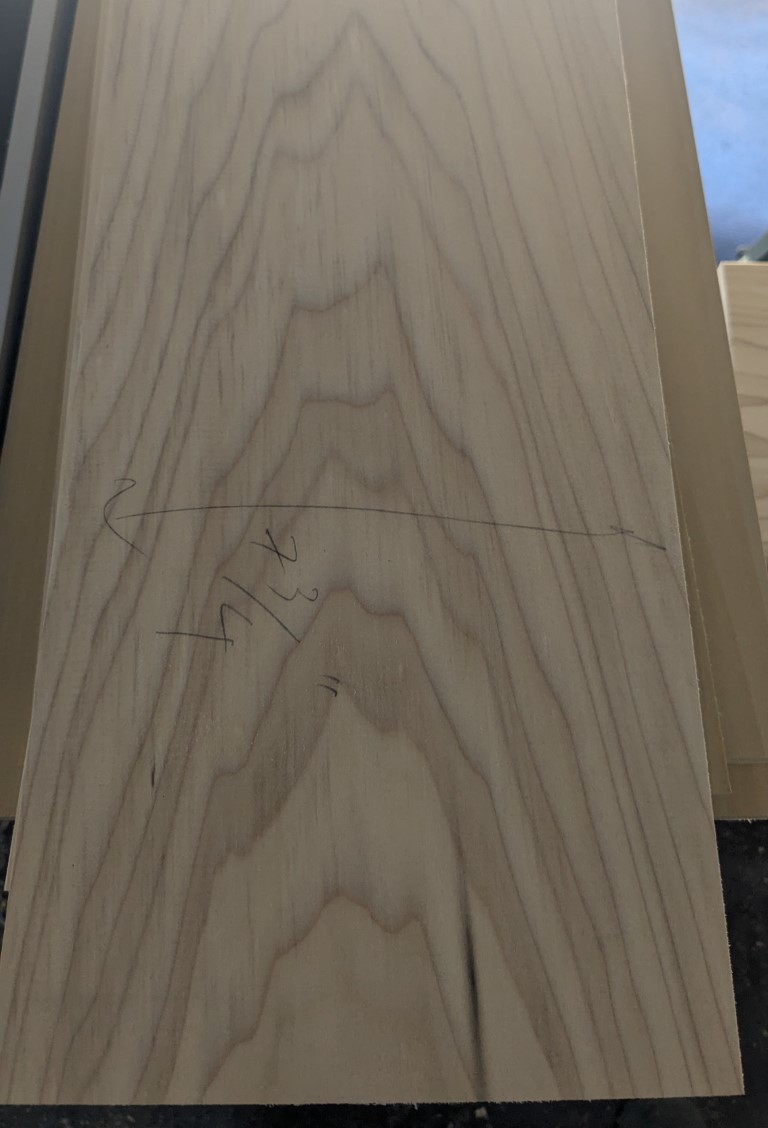

In the blink of an eye a month has passed. I’m happy to report that the stickered drawer sides stayed flat! I was particularly concerned with this board that displayed a “cathedral” grain pattern on its face - these boards tend to cup. If you look at the end grain (think round cross section of a tree trunk, the view from which you would count growth rings), you can imagine the board as a rectangular slice that was extracted from a set of concentric circles, and it should be obvious why these boards tend to cup.

Cutting the bottom groove

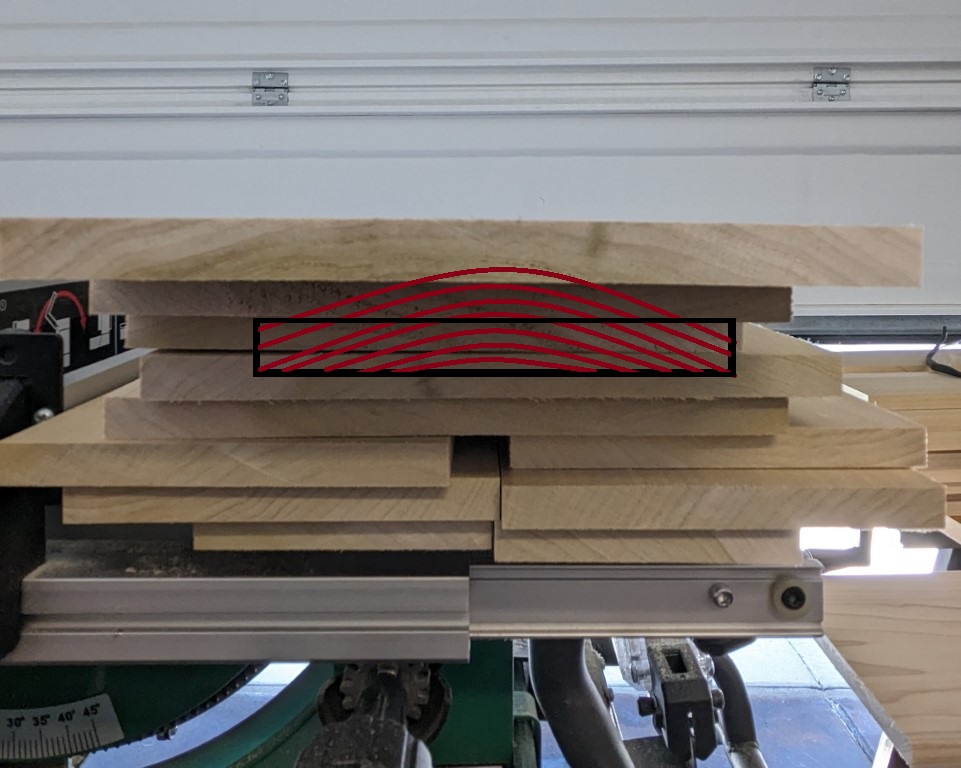

I lied when I said in the last post that the boards were ready for handwork. I actually decided to cut in the grooves (called dados in woodworking land) to hold the drawer bottoms. It’s a straightforward process: I went through all my boards to pick out the orientation (i.e. which side should be inside and which side should be the top). Then I set my table saw fence at 1/4” and made a first pass on the inside bottom of all the boards. There is something satisfying in brainlessly batching out work…

It’s important to use a flat top grind sawblade for cutting dados, otherwise the bottom will be uneven and your cut will have what’s affectionately known as ‘bat ears’. My blade is regular thickness at 1/8”, and I’m using 1/4” drawer bottoms which typically has an actual thickness of 7/32” or 6 mm depending on the source. Regardless, one pass of my sawblade is not wide enough, so I nudged the fence a little and took a second pass on all the boards. Of course before making this cut on all the sides its important to first dial in the fence position such that the dado will accept the drawer bottom easily without being too loose.

So satisfying to nail the fit. I had an offcut piece from the drawer bottom sheet so it made testing for fit easier. Alternatively, I could’ve tested the drawer side on the 8’ sheet…

And in a couple hours all the drawer sides are now actually ready for handwork! The actual time spent cutting was probably around 15 minutes… a large part of shop time is just moving material around, and an even larger part setting up and tearing down - probably the biggest drawback of woodworking out of a garage. But hey! Thanks for sticking around, and I hope your day is as groovy as mine was. Sorry, I’ll see myself out.